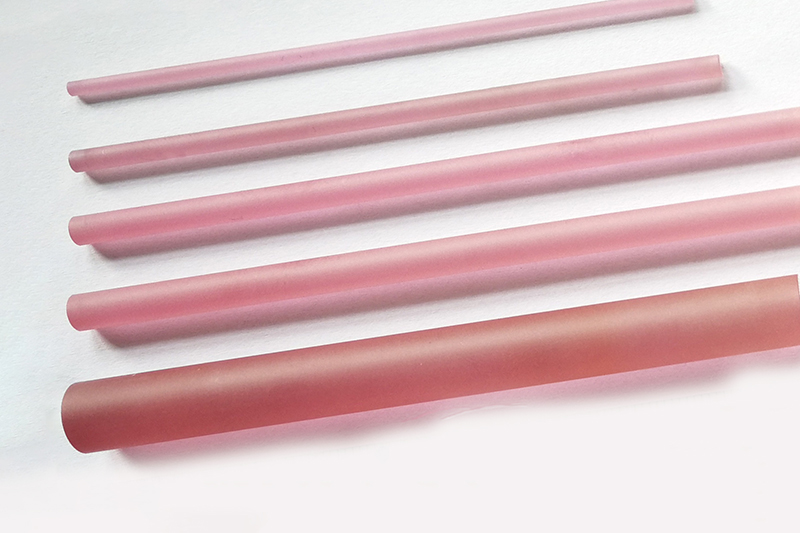

Yb:Iikristale ze-YAG

I-Yb:YAG yenye yezona zinto zithembisayo ngelaser-active materials kwaye ifaneleke ngakumbi ukumpompa idiode kuneenkqubo zeNd-doped zesintu.Xa kuthelekiswa ne-Nd esetyenziswa ngokuqhelekileyo i-Nd: YAG crsytal, i-Yb: i-crystal ye-YAG ine-bandwidth enkulu kakhulu yokufunxa ukunciphisa iimfuno zolawulo lwe-thermal kwii-laser ze-diode, ixesha elide lokuphila kwinqanaba le-laser, amaxesha amathathu ukuya kwamane aphantsi kokulayisha kwe-thermal kwiyunithi yempompo yamandla.I-Yb:Ikristale ye-YAG kulindeleke ukuba ithathe indawo ye-Nd: YAG yekristale yamandla aphezulu e-laser epump i-diode kunye nezinye izinto ezinokubakho.

Yb:YAG ibonisa isithembiso esikhulu njengesixhobo selaser samandla aphezulu.Izicelo ezininzi ziyaphuhliswa kwibala le-laser zoshishino, njengokusika isinyithi kunye ne-welding.Ngomgangatho ophezulu weYb:YAG ngoku iyafumaneka, iindawo ezongezelelweyo kunye nezicelo ziyajongwa.

Izinto eziluncedo zeYb:YAG Crystal:

• Ukufudumeza okusezantsi kakhulu, ngaphantsi kwe-11%

• Ukusebenza kakuhle kakhulu kwithambeka

• Iibhendi zokufunxa ezibanzi, malunga ne-8nm@940nm

• Akukho kufunxa kwimo echulumancisayo okanye uguqulo oluphezulu

• Ukumpontshwa ngokulula zii-InGaAs diode ezithembekileyo kwi-940nm(okanye 970nm)

• I-conductivity ephezulu ye-thermal kunye namandla amakhulu omatshini

• Umgangatho ophezulu wokukhanya

Usetyenziso:

• Ngebhendi yempompo ebanzi kunye necandelo elinqamlezileyo lokukhutshwa kwe-Yb:YAG yikristale efanelekileyo yokumpompa i-diode.

• Amandla oPhumo oluPhezulu 1.029 1mm

• Izinto zeLaser zokuPompa iDiode

• Ukwenziwa kweMathiriyeli, ukuWelding kunye nokuSika

Iinkcazelo ngeempawu ezisisiseko:

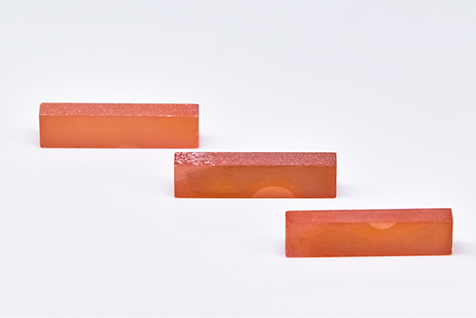

| Ifomula yeMichiza | Y3Al5O12:Yb (0.1% ukuya kwi-15% Yb) |

| Ulwakhiwo lweCrystal | Cubic |

| Isiphumo sobude beWaveleng | 1.029 um |

| Isenzo seLaser | 3 Level Laser |

| Ukukhutshwa kuBomi bonke | 951 kuthi |

| Refractive Index | 1.8 @ 632 nm |

| Iibhendi zokufunxa | 930 nm ukuya 945 nm |

| Impompo yobude bobude | 940 nm |

| Ibhendi yokufunxa malunga nobude bobude bempompo | 10 nm |

| Indawo yokunyibilika | 1970°C |

| Ukuxinana | 4.56 g/cm3 |

| Mohs Ubunzima | 8.5 |

| I-Lattice Constants | 12.01Ä |

| I-Coefficient yoKwandiswa kweThermal | 7.8×10-6/K , [111], 0-250°C |

| I-Thermal Conductivity | 7.8×10-6/K , [111], 0-250°C |

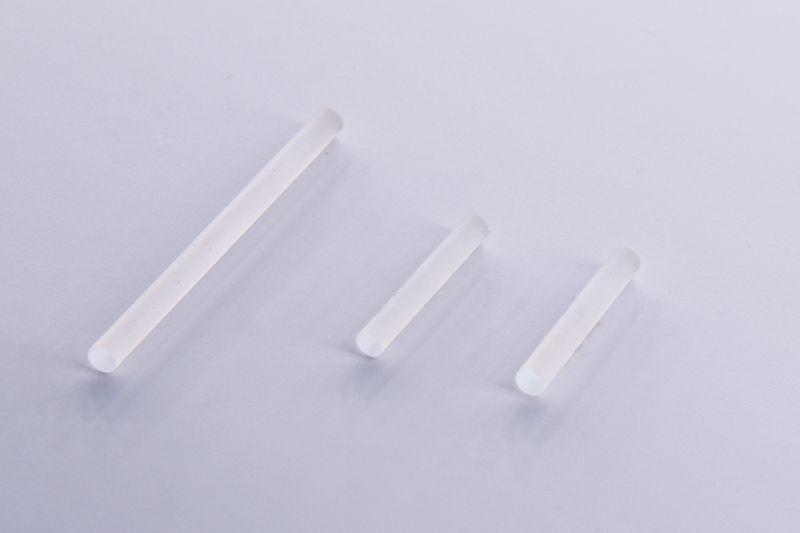

Iiparamitha zobuGcisa:

| Ukuqhelaniswa | ngaphakathi kwe-5 ° |

| Ububanzi | 3 mm ukuya kwi-10mm |

| Ukunyamezela kwe-Diameter | +0.0 mm/- 0.05 mm |

| Ubude | 30 mm ukuya kwi-150 mm |

| Ukunyamezela Ubude | ± 0.75 mm |

| Perpendicularity | 5 arc-imizuzu |

| Ukufana | 10 arc-imizuzwana |

| Ukucaba | 0.1 ubuninzi bamaza |

| Umphezulu Gqiba | 20-10 |

| Umphanda Gqiba | 400 grit |

| Phelisa iBevel yoBuso: | 0.075 mm ukuya kwi-0.12 mm kwi-angle ye-45 ° |

| Iitshiphusi | Akukho zitshiphusi ezivumelekileyo ekupheleni kobuso bentonga;I-chip enobude obuphezulu be-0.3 mm evunyelwe ukuba ilale kwindawo ye-bevel kunye ne-barrel surfaces. |

| Umngxuma ocacileyo | Embindini 95% |

| Iingubo | Ukwaleka okusemgangathweni yi-AR kwi-1.029 um kunye ne-R <0.25% ubuso bonke.Ezinye iingubo ezikhoyo. |

Iindidi zeemveliso

-

Ifowuni

Ifowuni

-

I-imeyile

I-imeyile

-

whatsapp

whatsapp

-

Wechat

Wechat

-

Phezulu